"We deeply understand what lead time, quality, aftersale service and price mean to our customers."

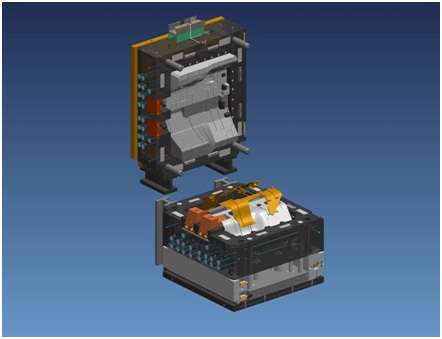

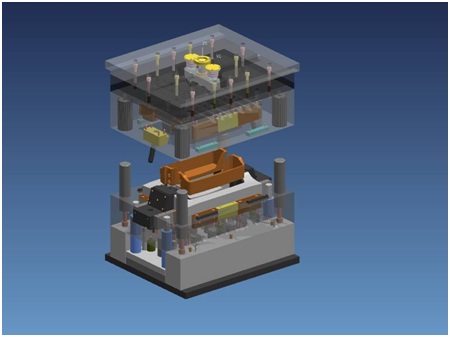

Injection Mold

MoldEuro offers complete precision mold design of plastic injection molds. With our high skilled technical team we can meet your individual requirements in the various branches of the industry. Some of them are as follows;

MoldEuro offers complete precision mold design of plastic injection molds. With our high skilled technical team we can meet your individual requirements in the various branches of the industry. Some of them are as follows;

- Consumer electronics

- Telecommunications

- Home appliances

- Power tools

- Vacuum cleaners

- Water drain pipe molds

- Automotive

- Printers and copiers

- Computer server

- Fittings

- etc.

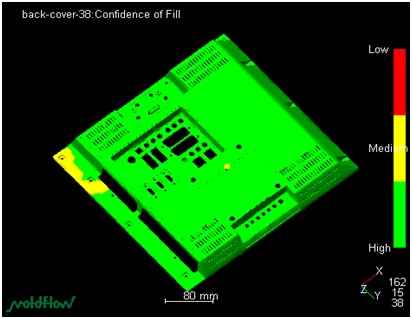

MoldEuro aims at creating a manufacturable design which absolutely meets your expectations. In the first instance, understanding your concept is very important in order to save money and time in manufacturing your design. We can use your hand drawn information and specifications to carry out design molds for your plastic parts or we can modify your existing parts in consideration with your new design.

We employ following engineering and mould-making technology for design of your parts:

- AutoCAD (2D Modeling)

- Solid Works (3D Modeling)

- Pro/ENGINEER (3D Modeling)

- UGS NX4.0 (3D Modeling)

Our high-skilled technical staffs have high level of experience in mold design and manufacture. Technologies like CAD, machining, analysis and reverse engineering are efficiently utilized in conformation to the standards for mould designing and manufacturing in DME, HASCO STRAND etc.

Our high-skilled technical staffs have high level of experience in mold design and manufacture. Technologies like CAD, machining, analysis and reverse engineering are efficiently utilized in conformation to the standards for mould designing and manufacturing in DME, HASCO STRAND etc.

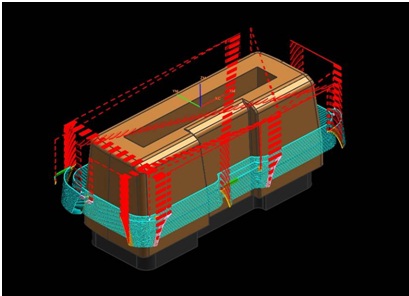

MoldEuro is capable of developing both cold runner and hot runner molds, two plate and three plate gas injection moulds and two-tone injection moulds etc. Moulds are manufactured by using sophisticated equipments like CNC, CMM, wire cutting, EDM and others, all with very high precision tolerance.

MoldEuro is capable of developing both cold runner and hot runner molds, two plate and three plate gas injection moulds and two-tone injection moulds etc. Moulds are manufactured by using sophisticated equipments like CNC, CMM, wire cutting, EDM and others, all with very high precision tolerance.

With the combination of our innovative designs, excellent skills and sophisticated facilities, we can successfully meet all your requirements cost-effectively in a very short time.